Advanced Solutions for Mineral Processing

Used extensively for the flotation of Many types of raw ore, the flotation mining reagents are well-suited for the recovery of precious and base metals,;such as gold, silver, platinum group metals, nickel, cobalt, lithium, phosphate, Iron, and copper.

It can be widely used in the flotation of oxidized ores and can achieve high recoveries with reduced environmental impact.

Different categories of solutions

Copper

Mining operators depend on the FFA-201c and FFA-205c copper flotation reagents to improve the recovery of copper from ores such as copper-nickel, copper-molybdenum and oxide copper.

Iron

The innovative reagents for iron ore flotation, including FAF-20F, FEC-16,and FFA-30F, address the diverse recovery challenges encountered in iron ore processing. These versatile solutions cater to varying mineralogy, particle sizes, and gangue compositions, ensuring optimal recovery rates.

Lithium and Spodumene

To address the increasing demand for lithium in applications like batteries, the FFA-10L flotation collectors enhance lithium recovery from hard-rock sources such as spodumene.

Phosphate

We provides a range of phosphine flotation chemicals to support the phosphate value chain, including FFA-40P collectors.

Gold and Silver

The FEC-035 flotation collectors enhance gold and silver recovery from complex ores. By selectively binding to precious metal particles, these collectors increase extraction efficiency and yield, meeting the high demand in jewelry, electronics, and investment industries.

Fluorite

The FFA-69y flotation collectors are designed to enhance fluorite recovery from various geological sources. These collectors optimize the flotation process by selectively binding to fluorite particles, increasing both the purity and yield of the extracted mineral, and meeting the growing demand in industries such as chemicals, ceramics, and metallurgy.

A Broad Portfolio for Mineral Processing

We presents a premier collection of flotation reagents designed to enhance metallurgical results. Our portfolio encompasses collectors for mineral flotation, frothers, depressants, and dispersants. Through collaborative partnerships with our clients, we innovate novel formulations and customized solutions to address the diverse challenges encountered in flotation operations.

Iron ore collector

FEC-16 - This line of reagents improves the efficiency of flotation separation processes for various ores and precious minerals. promoters operate in a wide range of alkalinity levels and complex conditions.

Sulfide Ore Collector

FFA-26s series is a sulfurous iron ore capture agent, with strong capture capacity, good selectivity, no smell and environmental protection,

Oxide Ore Collector

FFA-26s This product with good flotation performance and trapping performance, as well as foaming performance, good biodegradability, non-toxicity, easily soluble in water and strong washing ability.

Frothers

The FEC series Frohters improves trapping efficiency and reduces residual agent concentration in circulating water due to its strong adsorption on metal surfaces, benefiting environmental protection.

Heavy Metal Removal Agents

FEC-HMR reagents decreases Cd and As levels in phosphoric acid to achieve compliance with tightening regulations around animal feed and food safety.

Mining Wastewater Treatment Agents

FEC-WTC We provide high-quality, high-efficiency water treatment chemicals.

New Flotation Collectors

Although simple in concept, flotation is a complex process involving many physical and physicochemical sub-processes, each of which can significantly impact flotation efficiency. For instance, even a seemingly simple change in the flotation reagents employed can have a dramatic impact on outcomes.

Our flotation collectors are specifically designed according to mineralogical needs to enhance throughput, grade and recovery. They can provide superior kinetics and work across diverse alkalinity conditions. Offering higher selectivity than traditional sulfide ore flotation chemicals, our broad portfolio of flotation reagents includes collectors tailored for base metals, precious metals and polymetallics.

Product advantages (Xanthate Alternative Studies)

Characteristics of Xanthate

Easy to synthesize,

low priceStrong trapping ability,

Good water solubility,

Pollution to the environment,

Stinky odorPoor selectivity.

New Flotation Collectors

Stronger trapping capacity compared to xanthate,

Improved sulfur recovery,

Improved adhesion problems,

Improved mineral trap selectivity,

Safe and environmentally friendly,

No irritating odor.

As the application of Xanthate is becoming more and more restricted, the research on the substitution of yellow medicines has been emphasized and many technical achievements have been made.

Iron ore Collectors

Iron ore-FEC16

Achieve iron upgrading and silicon reduction in iron ore beneficiation, increase collection efficiency, and reduce pollution.

Application area, reverse flotation collectors for use in the flotation process, suitable for the separation of iron-bearing minerals such as hematite, magnetite, limonite, siderite, and rhodochrosite.

Core advantage

Appearance (250C) | Viscous substance |

Density (20°C, kg/m3) | ≥ 850 |

Active substance content | ≥ 65% |

pH acidity (5% aqueous solution) | 10-11 |

Iron ore Collectors

Core advantage

1、Excellent Medicinal Effect:

The collectors exhibit good solubility, dispersibility, and resistance to hard water. They offer strong selectivity and collection power, resulting in high-grade, high-recovery iron concentrates.

2、Low Ore Dressing Cost:

For iron ore reverse flotation desilication, the ore dressing cost is low, with desilication achieving below 3%.

3、Strong Temperature Adaptability:

Capable of achieving anionic ambient temperature flotation, demonstrating strong adaptability to changes in slurry temperature. Even at lower temperatures (10-14°C), satisfactory separation indices can be achieved.

4、Simple Operation:

Moderate flotation foam volume ensures stable flotation with a wide fluctuation range, facilitating production operations.

5、Safety and Environmental Protection:

The ore dressing process is safe and free from irritating odors, making it friendly to both human health and the environment.

Field Implementation Cases

Closed circuit test results:

| Use of capture agents | products | Yield/% | iron ore grade | recovery rate |

|---|---|---|---|---|

| FEC-16 | concentrates | 48.10 | 65.391 | 80.551 |

| tailings | 51.90 | 14.63 | 19.45 | |

| primary ore | 100.00 | 39.05 | 100.00 | |

| primordial agent | concentrates | 47.50 | 64.65 | 78.64 |

| tailings | 52.50 | 15.89 | 21.36 | |

| primary ore | 100.00 | 39.05 | 100.00 |

Iron ore concentrate grade 65.39%

Iron recovery 80.55%

Conclusions:

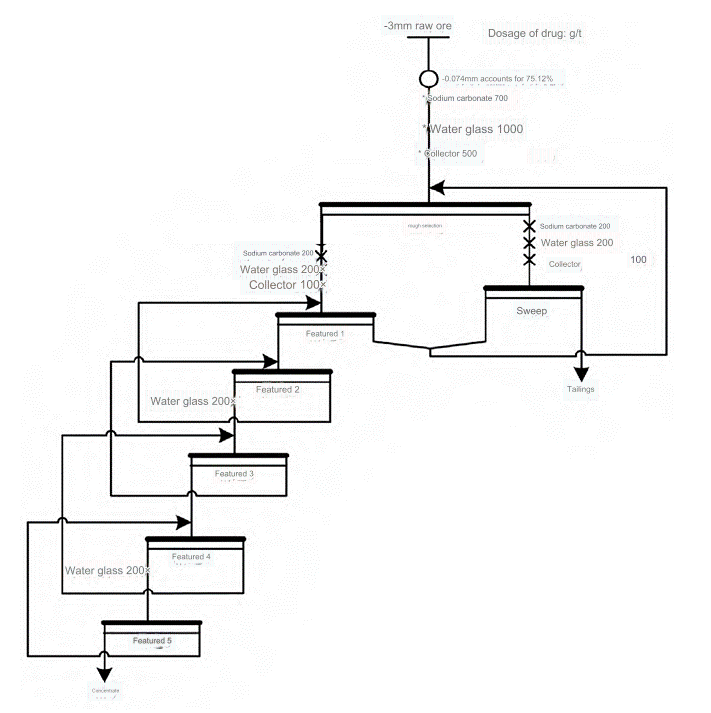

The sample was processed by using one coarse, one fine, three sweeps, and the middle ore sequential return process, and finally obtained an iron ore concentrate with iron grade upgraded by 1 degree and iron recovery upgraded by 2 degrees, which is a significant increase in iron recovery and grade compared with the original mine process.

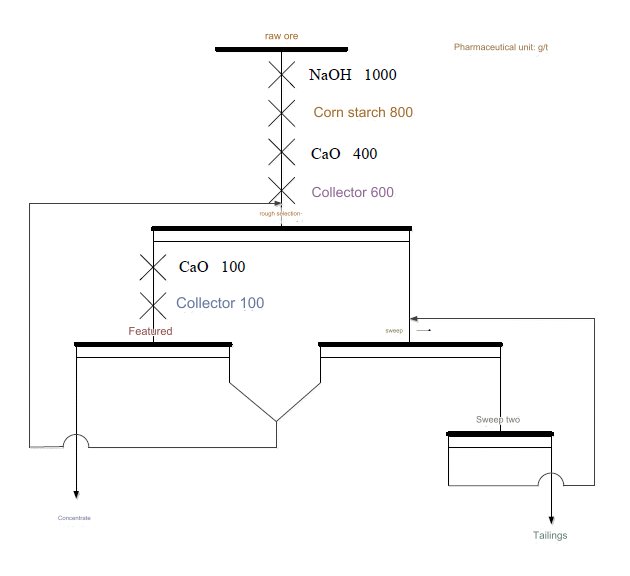

Sulfide Ore Collectors

FFA-26S

FFA-26S series is a sulfurous iron ore capture agent, with strong capture capacity, good selectivity, no smell and environmental protection, etc., has a very good effect on the separation of sulfurous iron ore; it can also be used in iron ore desulfurization, especially for difficult to select sulfur-containing minerals (magnetic pyrite, etc.) has a very good flotation effect, which can reduce the sulfur content of the iron ore to less than 0.1%.

Application area

It is suitable for flotation of sulfide ores such as copper sulfide ore, lead-zinc ore, molybdenum pyroxene, tungsten ore, copper-nickel ore, copper-zinc ore and other sulfide ores.

Core advantage

FFA-201 series is light yellow to brown oily liquid, slightly soluble in water, copper, lead, zinc and other sulfide ores selective recovery agent, especially for copper has a wide range of recovery capacity and selectivity, can be achieved at low alkalinity copper-sulfur separation, which can significantly improve the recovery of copper and associated elements of gold and silver; foam phenomenon is good, with fewer inclusions, which is conducive to improving the efficiency of sorting.

Customer Application

Source of ore samples: production samples from an iron ore mine in Northeast China

Basic requirements of the process:

Floating TFe grade | 50%~51% |

particle size of floating ore | - 0.037mm(85%) |

flotation temperature | 20±1℃ |

flotation concentration | 35% |

Flotation machine speed | 1600r/min |

filling capacity | 0.08 |

Use of chemicals:

l 1、Low temperature resistant trapping agent FEC-16

l 2、Original recovery agent for selecting plantTest flow:

l A closed-circuit test flow of 1 roughing, 1 concentrating and 2 sweeping is adopted, and the middle ore is returned in a sequential manner.

Comparison Case

Results of flotation closed-circuit experiments | ||||

Use of capture agents | Product name | Yield/% | Grade/% | Recovery rate/% |

concentrates | 63.37 | 68.20↑ | 85.08↑ | |

FEC-16 | tailing | 36.63 | 20.69 | 14.92 |

total | 100.00 | 50.80 | 100.00 | |

concentrates | 62.94 | 67.50 | 83.48 | |

primordial agent | tailing | 37.06 | 22.69 | 16.52 |

total | 100.00 | 50.89 | 100.00 | |

Iron ore concentrate grade 68.20%

Iron recovery 85.08%

From the results of the closed-circuit test, it can be seen that the use of FEC-16 as a test recovery agent achieved better test indexes than the use of mineral processing original recovery agent as a test recovery agent, the final iron ore concentrate grade of 68.20%, recovery of 85.08%, and also verified that the new type of low-temperature-resistant recovery agent FEC-16 has a better low-temperature-resistant performance than the original use of the recovery agent.

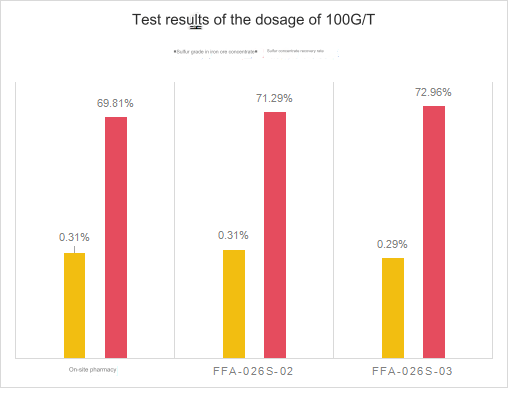

Test report on a new type of trapping agent for iron ore

1、The dosage of agent is 100g/t

Sulfur recovery in sulfur concentrate increased by 1.5% (FFA-026s-02)

Sulfur recovery in sulfur concentrates increased by 3 percent (FFA-026s-03)

2、The dosage of agent is 120g/t

Sulfur recovery in sulfur concentrate increased by 3.5% (FFA-026s-02)

Sulfur recovery in sulfur concentrates increased by 2.3% (FFA-026s-03)

Oxide Ore Collector

FFA-69Y

The series of eco-friendly fluorite flotation reagents are easily biodegradable, with characteristics of low-temperature resistance, good selectivity, and strong collecting ability. They can be widely used in various fluorite ore flotation processes (such as fluorite-quartz and fluorite-calcite) and other oxidized ores.

FFA-10L

The reagent series for lepidolite and spodumene flotation features strong adaptability, excellent collecting ability, and good selectivity. It is also suitable for low-temperature environments and high-clay ores.

FFA-40P

The reagent series for phosphate ore flotation and dephosphorization of phosphorus-containing iron ore offers good selectivity for phosphorus minerals like apatite and strong collecting ability. It provides a high phosphorus enrichment ratio, is cost-effective, and easy to use.

FFA-201c and FFA-205c

It can be used in the flotation of copper oxide, copper sulfide, copper-nickel, and copper-molybdenum ores. It is especially effective for copper oxide and mixed oxide-sulfide ores, offering high recovery rates, good selectivity, and stable performance. It surpasses yellow medicine in efficiency and is a new, non-toxic, environmentally friendly ore-dressing agent.

FFA-366T

The reagent is used for ilmenite flotation, offering excellent flotation and collecting performance. It has strong acid resistance, foaming properties, good biodegradability, is non-toxic, and easily dissolves in water.

FFA-10B

The reagent has a strong and selective collecting action for aluminosilicates and potassium salts such as quartz, feldspar, and mica. It has good collecting ability, selectivity, and foaming capacity. Containing various active substances, it enhances the hydrophobicity of carbonate and silicate minerals, improving overall recovery rates.

Fluorite Ore Flotation Case

On-site beneficiation process system and advantages :

High Efficiency in Collection:

The fluorite collector demonstrates superior collection performance, with experimental data showing a 10% increase in collection efficiency compared to traditional collectors under the same conditions, significantly improving the recovery rate of ore.

Good Selective Collection:

The fluorite collector has excellent selectivity, effectively distinguishing between target and non-target minerals, reducing impurities, ensuring ore quality, and enhancing the grade of concentrate.

Environmentally Friendly

The fluorite collector has a minimal environmental impact during production and use, meeting the needs of green mining development, while reducing production costs and enhancing the market competitiveness of the enterprise.

Product name | recovery rate | grade | recovery rate |

concentrates | 60.22 | 98.01 | 93.68 |

after processing ore | 39.78 | 10.01 | 6.32 |

raw ore | 100 | 63.00 | 100.00 |

Frothers

The chemistry of froth flotation holds considerable sway over the flotation process, influencing everything from preventing bubble merging to stabilizing bubble size and particle attachment, and even enhancing bubble residence time and surface area flux. Modern froth flotation methods depend heavily on alcohol and polyglycol-based chemical formulations. When customized effectively, these frothers foster optimal hydrodynamic environments, thereby maximizing yields.

We offers a diverse array of flotation agents, leveraging alcohol-based, glycol-based, and blended formulas to enhance the efficiency of various flotation systems. Our team of experts plays a vital role in assessing flotation circuits, identifying the most effective chemical schemes to optimize froth flotation performance.

Suitable for flotation frothing of various minerals.

This series of products includes frothers FFA-501q、FFA-176q、FFA-186q, etc.

Based on different ore properties, the company has developed a series of specialty frothers suitable for all types and varieties of ores

Core Advantages

Active substance content ≥90,

Strong foaming ability, fast foaming speed, stable foam layer,

Good dispersibility of foam in the subsequent flotation section,

Easy biodegradation, safe and environmentally friendly.

Frother agent application

A copper-sulfur ore beneficiation in Guangdong Province

A Guangdong copper-sulfur ore plant used our FFA-501q as a frother in weakly alkaline pulp at pH 9, achieving a 28.51% copper concentrate grade and a 94.50% recovery rate. Replacing No. 2 oil with FFA-501q significantly enhanced economic outcomes. FEC series flotation foaming agent is stable in quality, non-toxic, and has no corrosive effect on metal.

Frothers Core advantage

Active substance content ≥90% the FFA-501q frother not only improves capture efficiency but also reduces the concentration of residual agents in circulating water due to strong adsorption on metal surfaces, which is beneficial for environmental protection.

The frother, with strong adsorption on metal surfaces, enhances collection while lowering the residual concentration in circulating water, aiding environmental conservation.

Stable in quality, non-toxic, and non-corrosive to metals, the frother combines foaming and collecting properties, offering fast flotation, uniform foam, high strength, and good selectivity. It can save 15%-35% on oil when used alone or significantly reduce costs when mixed with other agents.

With comparable concentrate yield and grade to similar products, the frother offers ideal flotation time and a suitable defoaming rate of 4-6mm/s.

Strong foaming ability, rapid foam generation, stable foam layer

Good brittleness of foam in subsequent flotation stages

The reagent is easily biodegradable, safe, and environmentally friendly.

Depressants for Froth Flotation

Depressants are key in ore separation during froth flotation, either by inhibiting gangue to float the target mineral or by suppressing the target mineral to allow gangue to float. This selective depression is vital for complex, high-impurity ores. Depressants are crucial for maximizing yields and concentrate grades.

Our experts, with deep flotation process knowledge, have developed an efficient and versatile range of depressants. These technologies are effective at lower doses than traditional chemistries like water glass and CMC..

FFA-DLE

DEL is an effective inhibitor for sphalerite, pyrite, and marcasite. In the flotation process of a lead-zinc polymetallic ore, DEL can be used in combination with sodium sulfite and zinc sulfate, where the three have a synergistic effect. Adding a small amount of DEL significantly enhances the inhibitory effect of sodium sulfite and zinc sulfate on activated sphalerite.Suitable for the flotation of ores containing one or more of sphalerite, pyrite, and marcasite.

FFA-10N

Common inhibitors like water glass, CMC, starch, and guar gum can cause difficulties in concentrate filtration due to their high viscosity. The newly developed clay mineral inhibitor FFA-10n is not a conventional market combination, has low viscosity, and its pH can be adjusted. It is unaffected by temperature during flotation. FFA-10n has a strong inhibitory effect on altered minerals but a weaker effect on target minerals, offering good selective inhibition. The inhibitor acts quickly and effectively, making easily floatable vein minerals more hydrophilic without affecting the floatability of valuable minerals, significantly improving the concentrate grade.

Experimental study on the beneficiation of magnesium-molybdenum-iron ores

Application area

Silicate minerals in the ore, such as serpentine and talc, can cause froth stickiness and poor selectivity in flotation, increasing reagent use and magnesium oxide in the concentrate.

FFA-10n is a selective depressant that strongly inhibits altered minerals but has a mild effect on valuable minerals like molybdenite. It acts fast, improves selectivity, and enhances concentrate quality without affecting the floatability of useful minerals

About the factory

The largest production base for specialized heavy metal treatment chemicals.

The production base is located in the high-tech Industrial Park of Linxiang City, Yueyang, covering an area of 110 acres, with a production capacity of 165,000 tons/year.

For more information & free sample, please contact

Shawn Ge

Walsun Tech & Trade Co., Ltd.

Tel/Mobile(WhatsApp): 0086-13974873008

Fax: 0086-731-82233558

Email: shawn.ge@walsun.cn